TPU Base Film yog dab tsi?

TPU zaj duab xis yog ib zaj duab xis ua los ntawm TPU granules los ntawm cov txheej txheem tshwj xeeb xws li calendering, casting, zaj duab xis tshuab, thiab txheej.Vim tias TPU zaj duab xis muaj cov yam ntxwv ntawm cov dej noo permeability, huab cua permeability, txias tsis kam, kub tsis kam, hnav tsis kam, siab nro, siab rub quab yuam, thiab siab load txhawb, nws daim ntawv thov yog dav heev, thiab TPU zaj duab xis tuaj yeem pom nyob rau hauv txhua yam. ntawm lub neej niaj hnub.Piv txwv li, TPU films yog siv nyob rau hauv ntim cov ntaub ntawv, lub tsev pheebsuab yas, dej zais zis, lub nra composite fabrics, thiab lwm yam. Tam sim no, TPU films mas siv nyob rau hauv cov xim tiv thaiv zaj duab xis nyob rau hauv lub automotive teb.

Los ntawm cov qauv kev pom, TPU xim tiv thaiv zaj duab xis yog tsim los ntawm kev ua haujlwm txheej, TPU puag zaj duab xis thiab nplaum txheej.Ntawm lawv, TPU puag zaj duab xis yog qhov tseem ceeb ntawm PPF, thiab nws qhov zoo yog qhov tseem ceeb heev, thiab nws cov kev ua tau zoo yog qhov siab heev.

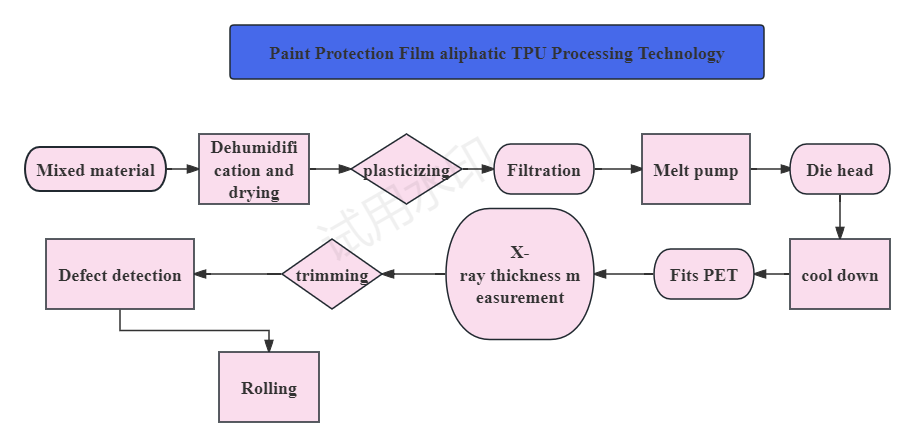

Koj puas paub cov txheej txheem tsim khoom ntawm TPU?

Dehumidification thiab ziab: molecular sieve dehumidification desiccant, ntau tshaj 4h, noo noo <0.01%

Cov txheej txheem kub: xa mus rau cov khoom lag luam raw khoom pom zoo, raws li hardness, MFI nqis

Lim: ua raws li lub voj voog ntawm kev siv, txhawm rau tiv thaiv cov xim dub ntawm cov khoom txawv teb chaws

Melt twj: extrusion ntim stabilization, kaw-voj tswj nrog lub extruder

Ntsia Hlau: Xaiv cov qauv qis qis rau TPU.

Tuag lub taub hau: tsim cov dej ntws raws li rheology ntawm aliphatic TPU khoom.

Txhua kauj ruam yog qhov tseem ceeb rau kev tsim PPF.

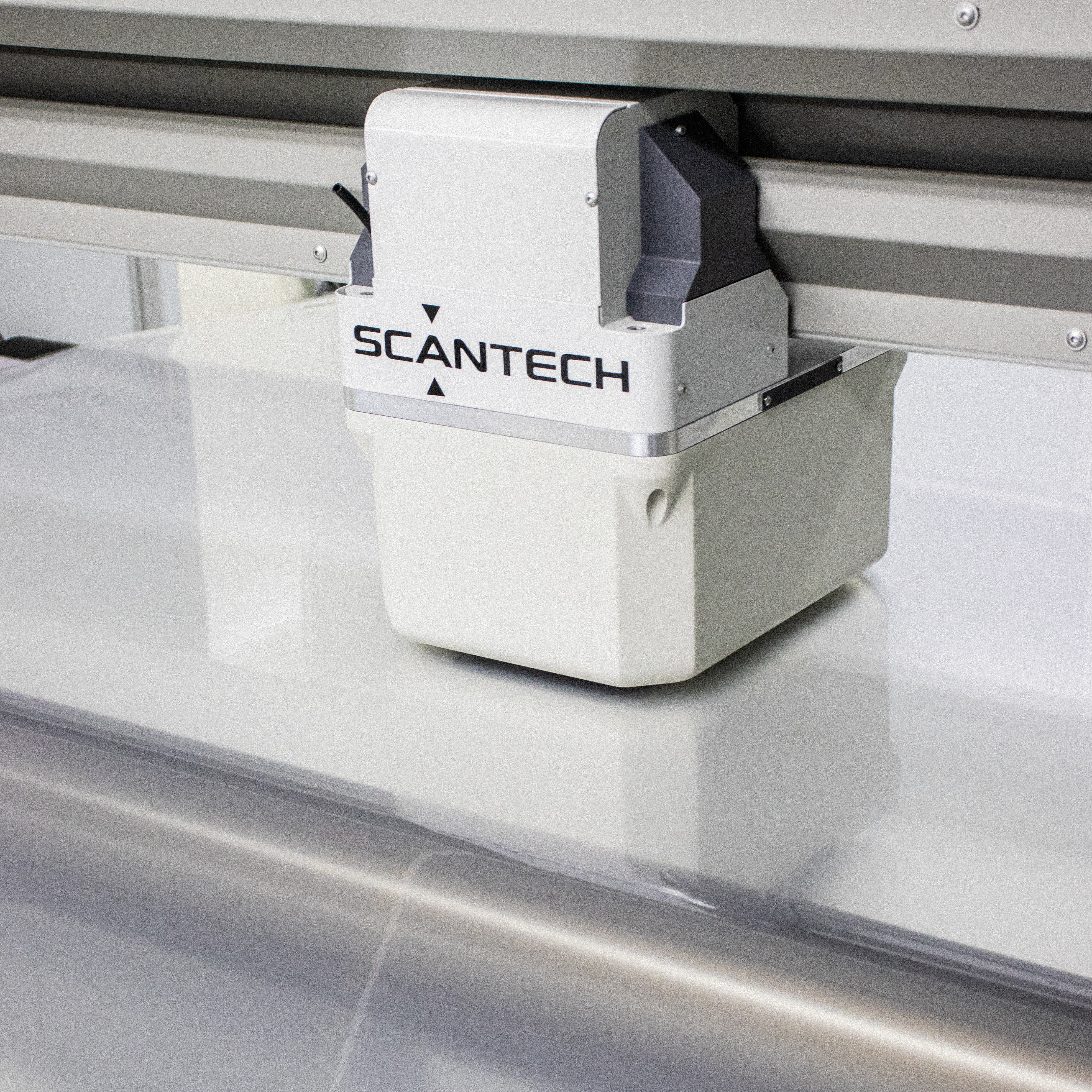

Daim duab no luv luv piav qhia txog tag nrho cov txheej txheem ntawm kev ua aliphatic thermoplastic polyurethane los ntawm granular masterbatch rau zaj duab xis.Nws suav nrog cov qauv sib xyaw ntawm cov khoom siv thiab dehumidification thiab ziab kom qhuav, uas ua kom sov, txiav thiab plasticizes cov khoom siv rau hauv melting (melt).Tom qab lim thiab ntsuas, qhov tsis siv neeg tuag yog siv los tsim, txias, haum rau PET, thiab ntsuas qhov tuab.

Feem ntau, X-ray thickness ntsuas yog siv, thiab kev tswj tsis pub lwm tus paub nrog kev tawm tswv yim tsis zoo los ntawm lub taub hau tuag tsis siv neeg.Thaum kawg, ntug txiav yog ua.Tom qab kuaj xyuas qhov tsis xws luag, cov neeg soj ntsuam zoo tshawb xyuas cov yeeb yaj kiab los ntawm ntau lub kaum sab xis kom pom tias cov khoom siv lub cev ua tau raws li qhov yuav tsum tau ua.Thaum kawg, cov yob tau dov thiab muab rau cov neeg siv khoom, thiab muaj cov txheej txheem maturation nyob nruab nrab.

Ua cov ntsiab lus thev naus laus zis

TPU masterbatch: TPU masterbatch tom qab kub kub

tshuab casting;

TPU zaj duab xis;

Txheej tshuab gluing: TPU muab tso rau ntawm lub thermosetting / teeb-teeb txheej tshuab thiab coated nrog ib txheej ntawm acrylic kua nplaum / lub teeb-kho kua nplaum;

Laminating: Laminating PET tso zaj duab xis nrog cov nplaum TPU;

Txheej (ua haujlwm txheej): nano-hydrophobic txheej ntawm TPU tom qab lamination;

Kev ziab: ziab cov kua nplaum rau ntawm zaj duab xis nrog cov txheej txheem ziab uas tuaj nrog lub tshuab txheej;cov txheej txheem no yuav tsim ib qho me me ntawm cov organic pov tseg roj;

Slitting: Raws li qhov yuav tsum tau ua, cov zaj duab xis sib xyaw yuav raug txiav rau ntau qhov sib txawv los ntawm lub tshuab slitting;cov txheej txheem no yuav tsim cov npoo thiab cov ces kaum;

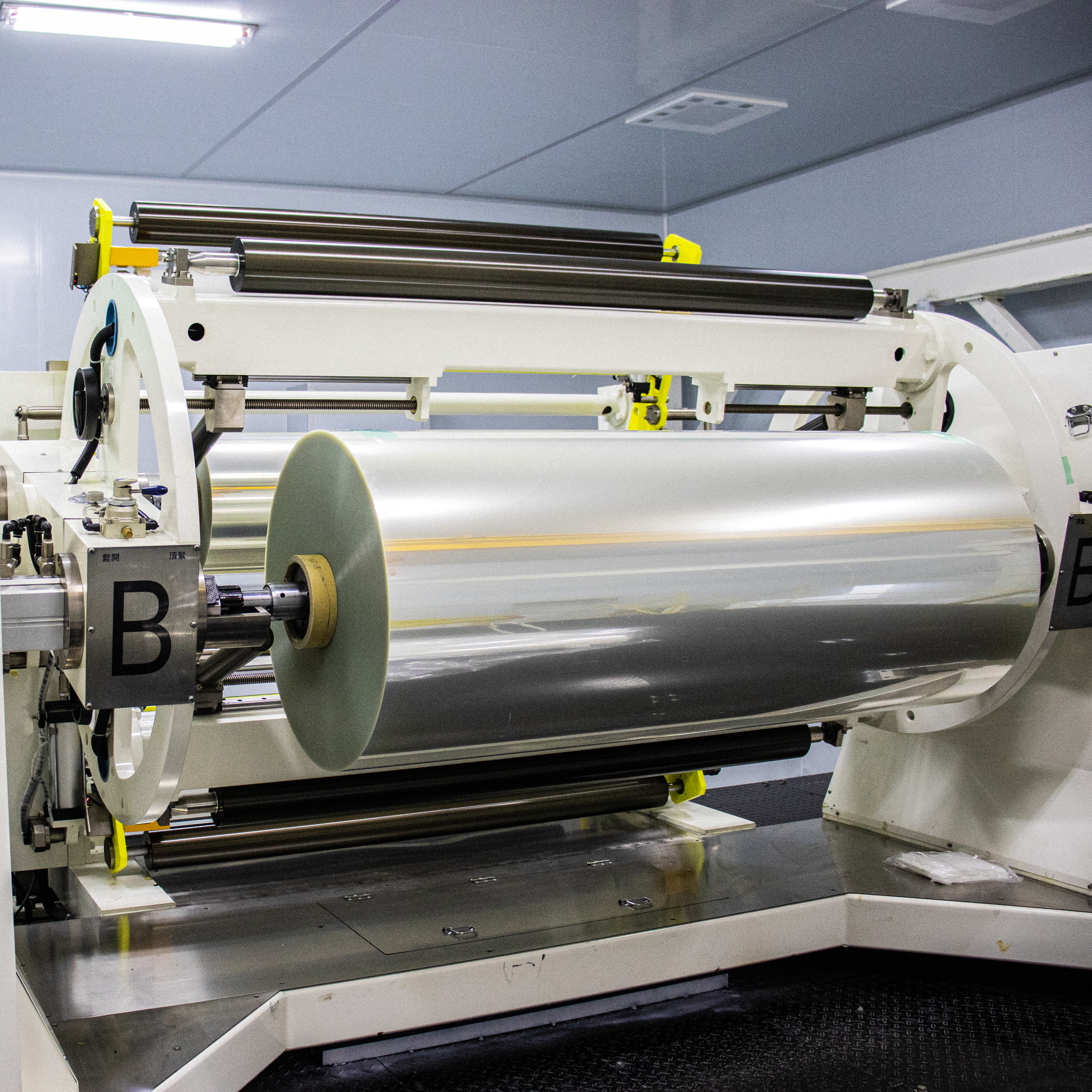

Rolling: xim hloov zaj duab xis tom qab slitting yog qhov txhab rau hauv cov khoom;

Kev ntim khoom tiav: ntim cov khoom rau hauv lub tsev rau khoom.

Daim duab txheej txheem

TPU masterbatch

Qhuav

Ntsuas tuab

Txiav

Rolling

Rolling

Yob

Thov luam theej QR code saum toj no kom tiv tauj peb ncaj qha.

Post lub sij hawm: Feb-23-2024